Simple integration of preceding processes thanks to modular cleanroom solution

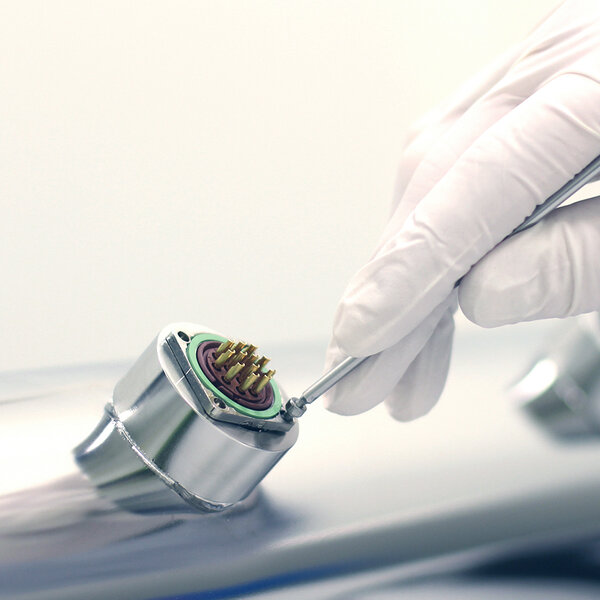

For use in medical technology, metering valves are to be manufactured in a cleanroom compatible manner. For this purpose, a room was required that integrates the preceding process into the cleanroom in a fully automated process so that time-consuming cleaning is no longer necessary. In the preceding process, individual components for metering valves are manufactured. The individual components are then assembled in the cleanroom using an automatic assembly machine.

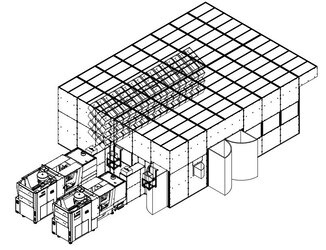

With the modular cleanroom elements, it was possible to create a 115 m² cleanroom with a plenum. The flush modules can be easily cleaned in accordance with the requirements of medical technology. The cleanroom has a material pass-through and a personnel airlock and achieved cleanroom class 7 according to DIN ISO 14644-1 in the initial qualification.

Customer benefit: Modular cleanroom concept for flexible adaptation of the room to changing conditions.

The automatic transfer of plastic parts for further processing in the cleanroom takes place directly after machine production in the plastic injection molding process via a special enclosure with integrated FFU and ionization. The plastic parts no longer have to be cleaned and transferred to the clean room before further processing steps.

The cleanroom can be adapted to changing requirements at any time thanks to its modular design. With little effort and low costs, wall modules and ceiling modules can be exchanged, removed or added so that the cleanroom size corresponds to the actual requirements.

learn more:

Reference: Modular cleanroom with integration of preceding processes

- 115 m² cleanroom area with one material pass-through and one personnel airlock

- Clean room class according to DIN ISO 14644-1 class 7

- Modular design to be able to react flexibly to changing processes

- Automated integration of preceding processes

Your contact persons in the department Sales Technical Cleanliness & Cleanroom

Lukas Kröber

Sales technical cleanliness & cleanroom

Planner technical cleanliness and cleanroom

- phone: +49 36604 8860

- Fax: +49 36604 88623

- vertrieb(at)mkf-automation.de