Our services

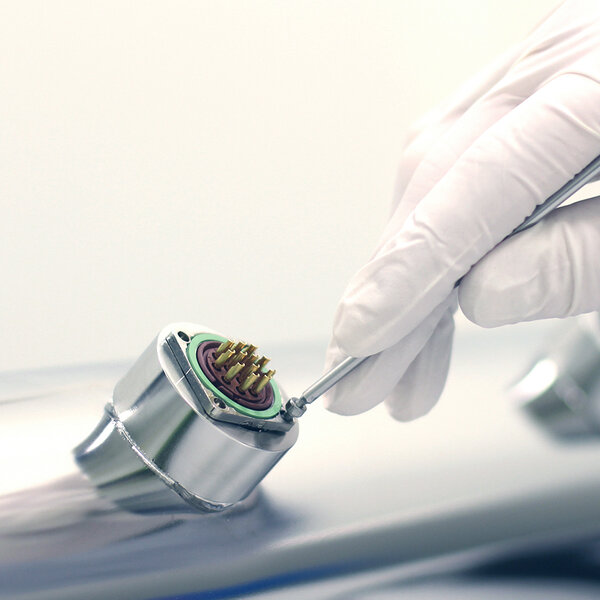

The topic of technical cleanliness (according to VDA 19 Part 2) and cleanroom (according to DIN ISO 14644-1) has accompanied us in our daily work for many years. In our own production and assembly, we are regularly faced with the task of observing and implementing cleanliness and purity specifications - if necessary also in our own clean room.

Defined environmental conditions also play an increasingly important role for our customers and suppliers in order to ensure process requirements in the areas of manufacturing, further processing and assembly. The focus here is on the long-term functionality of products. While for some, ambient conditions within the scope of technical cleanliness according to VDA 19 Part 2 are enough, others require clearly defined cleanroom conditions to protect small parts and assemblies from contamination by particles.

Weitere Leistungen im Überblick

Consulting on VDA‑19 part 2

When implementing your cleanliness requirements in accordance with VDA 19 Part 2, we support you by carrying out an actual state analysis and work with you to develop a solution for the realization of customer requirements with regard to the technical cleanliness of your components.

Read more...

Wide range of cleanliness and purity requirements

| non-regulated area |

|

|---|---|

| Clean Zone |

|

| clean room (according to VDA 19 part 2) |

|

| cleanroom |

|

For more and more industries and production processes, it is important to create a controlled environmental condition. We would be happy to advise you on the basis of your cleanliness and purity specifications on the topics of technical cleanliness (in accordance with VDA 19 Part 2) and cleanroom (according to DIN ISO 14644-1).

We also offer you a large service portfolio around the cleanroom:

- Work under cleanroom conditions

- Consulting on technical cleanliness (VDA 19 Part 2) and cleanroom (DIN ISO 14644-1)

- Orbital welding for components in cleanroom applications

- Cleanroom compatible cleaning and packaging

- Cleanroom cabins and modular cleanroom

- Cleanroom equipment

- Automation solutions in process adapted minienvironments

- Flow box systems

Certificates

mkf works for customers with innovative products and high precision requirements. Therefore, our internal work processes are certified according to DIN EN ISO 9001:2015 and DIN EN ISO 14644-1 (class 6) by TÜV Rheinland Cert GmbH.

Contact

Lukas Kröber

Sales technical cleanliness & cleanroom

Planner technical cleanliness and cleanroom

- phone: +49 36604 8860

- Fax: +49 36604 88623

- vertrieb(at)mkf-automation.de