mkf enables you to work economically and safely without purchasing new equipment. By converting, modernising or retrofitting machines or plants, you can efficiently increase productivity in your company. In addition, we modify your equipment for further tasks and adapt it to new Machinery Directives. We can also realise the optimisation in individual steps. This reduces investments and ensures an undisturbed production process. With a lot of know-how, our employees support you in the cost-efficient conversion and upgrading of existing plants.

Your advantages:

- Cost savings

- Faster amortisation

- Short business interruption times

- Lower risk

- Shorter training periods

Further information

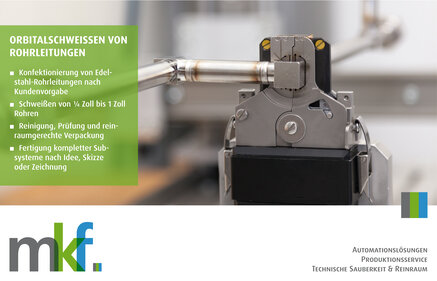

Orbital welding of pipelines

- Fabrication of stainless steel piping with connecting parts according to customer specifications.

- Welding is carried out in the range from ¼ inch to 1 inch

- Testing and clean room compatible packaging

- Manufacturing of complete subsystems according to idea, sketch or drawing

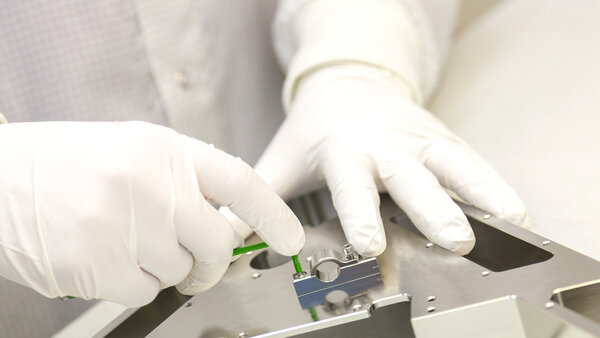

Service portfolio in the cleanroom

- Production of individual parts, components and assemblies under cleanroom conditions

- Cleaning and packaging for cleanroom-compatible production

- Delivery of cleanroom-ready and ready-to-install mechanical, electrical and mechatronic assemblies

- Development of cleanroom workstations and mini-environments

Contact

Michaela Oeser

Technical Sales Production Service

- phone.: 036604 8860

- Fax: 036604 88623

- vertrieb(at)mkf-automation.de

Thomas Bärsch

Technical Sales Production Service

- phone.: 036604 8860

- Fax: 036604 88623

- vertrieb(at)mkf-automation.de

Annegret Weise

Internal Sales Production Service

- phone.: 036604 8860

- Fax: 036604 88623

- vertrieb(at)mkf-automation.de

![[Translate to English:] Prozess- und Anlagenoptimierung](/fileadmin/_processed_/1/9/csm_3_3_Header_Optimierung_0dcc82073f.jpg)