One dimension, many possibilities: the modular cleanroom

The basic concept of clean room for industrial production and cleanroom is essentially the same. They differ primarily in terms of relevant particle spectrum and the ventilation and filter system required. Whereas in the clean room for industrial production particals are tolerated on components up to 600 µm, a much lower value applies in the cleanroom. In the cleanroom, airborne particles down to 5 µm are monitored.

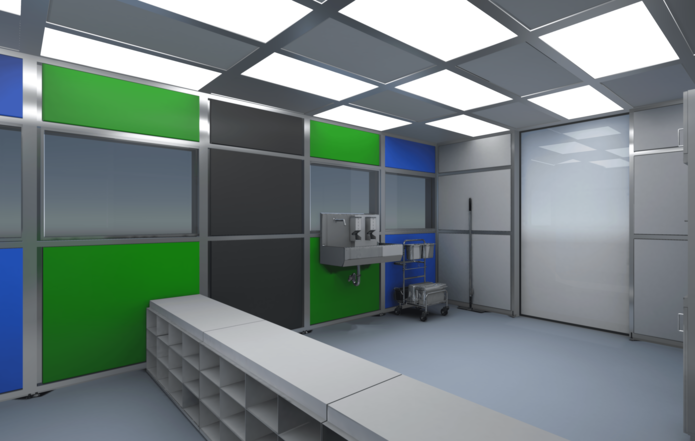

Based on aluminium profile witj closed grooves, mkf has developed a flexible cleanroom system which can be adapted to your individual requirements again and again. The advantages of the aluminium profile system are combined with the requirements of a cleanroom. From the different concealed wall and ceiling modules, you can configure the cleanroom that perfectly siuts your current needs. If your requiremnts change, simply change your cleanroom with minimal effort.

Individual design and flexible adaption to changed processes:

- quick assembly on site

- pre-assembled modules

- Flush wall system - also with window

- Individual assignment in the ceiling grid

- Energy-saving LED panels

- Powerful FFus with H14 filter

- Connection of upstream or downstream automated processes

We integrate your processes:

Do you want to adapt the cleanroom to your upstream or downstream automaed processes? We would be happy to advise and support you in the design and implementation.

Individual design:

Give your cleanroom its own identity and use color accents for an individual design. All closed surfaces are available as standard in white, metallic silver and many other standard colors.

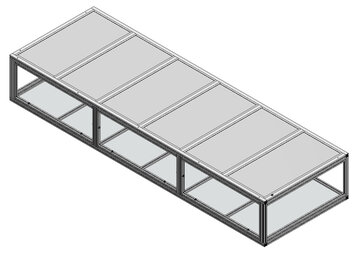

Configure your individual cleanroom from our wall and ceiling modules

Wall modules:

Dimensions basic module: approx. 1280 mm x 2800 mm (subdivided int 3 fields)

- Wall module 1: filling closed

- Wall module 2: filling of insulating glass in the middle, closed at the top and the bottom

- Wall module 3: filling of insulating glass in the middle, return air at the bottom, filling closed at the top

- Wall module 4: filling with return air at the bottom, closed at the middle and top

Ceiling modules:

- Dimension basic module: approx. 1280 mm x 3880 mm with 6 fields

6 filling elements can be selected freely for each ceiling module:

- Inspection opening

- FanFilterUnit: natural aluminium, 1.170 m³ @230 Pa

- H14 filter: filtration efficiency = 99,995%, temperature resistent 70 Grad/100 % RF

- lighting unit: LED panel daylight white - 6000K, 80 Watt, 6000Im, dimmable

Ceiling module with plenum:

- dimensions plenum module: approx. 1280 mm x 3880 mm x 600 mm

- Filling elements made of rigid foam PVC

Additions:

- Doors (single or double leaf)

- High-speed doors

- Matirial locks

Certificates

mkf works for customers with innovative products and high precision requirements. Therefore, our internal work processes are certified according to DIN EN ISO 9001:2015 and DIN EN ISO 14644-1 (class 6) by TÜV Rheinland Cert GmbH.

Contact

Lukas Kröber

Sales technical cleanliness & cleanroom

Planner technical cleanliness and cleanroom

- phone: +49 36604 8860

- Fax: +49 36604 88623

- vertrieb(at)mkf-automation.de

Weitere Leistungen im Überblick

Consulting on VDA‑19 part 2

When implementing your cleanliness requirements in accordance with VDA 19 Part 2, we support you by carrying out an actual state analysis and work with you to develop a solution for the realization of customer requirements with regard to the technical cleanliness of your components.

Read more...

![[Translate to English:] Modularer Reinraum](/fileadmin/_processed_/f/0/csm_4_3_Header_Modularer_Reinraum_b0112b848c.jpg)