Flexible parts storage with the LiFo storage system from mkf

With the LiFo storage system (feeder with storage) you get a stand-alone solution for the flexible storage of workpieces with backup times of up to 16 hours for your assembly line or packaging machine as well as processing line, for example in the night shift, to expand your capacities or to compensate for personnel shortages. The integrated cobot (collaborating robot) UR5e enables it to take over various handling tasks after convienient adjustment of the parameters. The LiFo storage system takes over the loading and unloading of your equipment, component testing, various measuring tasks or several assembly steps. By using a servo gripper, the LiFo storage system handles your vulnerable parts (for example, glass, ceramics) very gently. The LiFo storage system has an OPC UA interface. The OPC UA interface provides a manufacturer-independent optimal data transfer, to upstream or downstream plants/machine parts or to a PDA system without additional programming.

With its convenient transport option, the LiFo storage system can be used flexibly in your production. You can position the LiFo storage system using the integrated transport rollers. For larger distances, holders for industrial trucks are incorporated.

Workpieces are picked up in the task-specific modified workpiece carrier (in the standard version with a pick-up area of 250 x 400 mm and a max. total weight of 40 kg/workpiece carrier).

The mkf LiFo storage consists of the following main assemblies:

frame made of mk - aluminum profile system

- To hold the storage and conveyor combination, the cobot and the electrical installation

- Openings are closed with transparent polycarbonate panes

- Safety-monitored flaps for convenient loading and unloading

- Maintenance door on the back side

- Dimensions (L x W x H): approx. 1500 x 1500 x 2400 mm

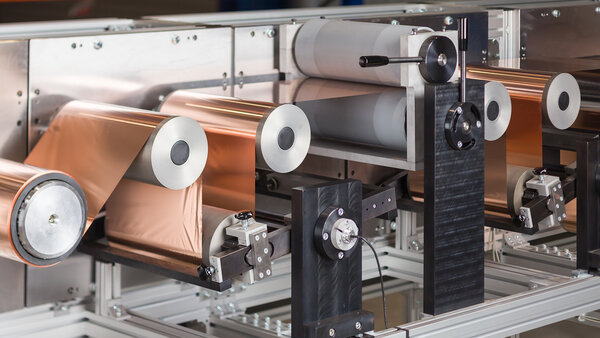

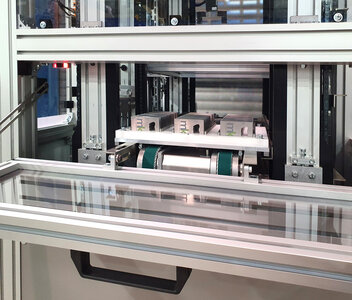

storage and conveying combination

- Consisting of 2 double strand chain conveyors and one toothed belt conveyor

- The chain conveyors store the workpiece carriers

- Toothed belt conveyor for transporting the workpiece carriers to the working position of the cobot

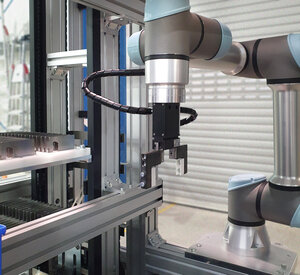

universal robots UR5e

- Collaborating robot

- 6-axis, movement radius 850 mm

- Payload 5 kg

- Integration into Universal's Polyscope software environment using URCap mkf LiFo memory

- Control via UR5e operator panel

- Integrated recipe management

- Easy editing of parameters through user-oriented GUI

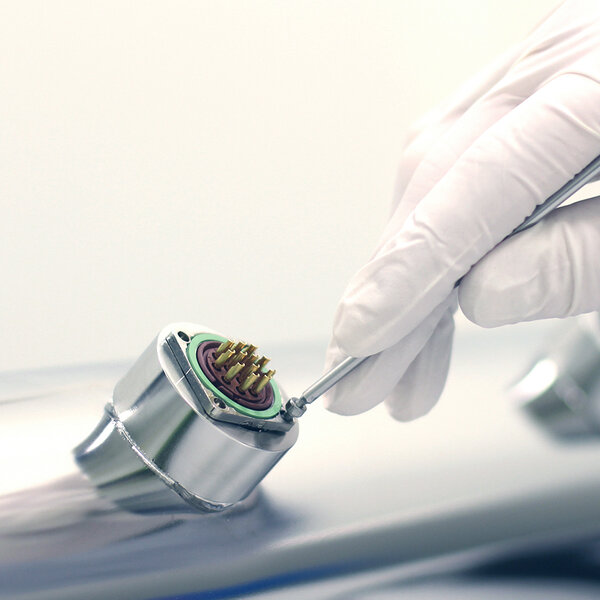

Zimmer 2-jaw parallel gripper GEP2000

- Large range with small installation space

- High flexibility when changing parts due to the large adjustment range, no setup effort or readjustment of the initiators necessary

- Easy integration into the control system (IO-Link)

- No pneumatics required - reduction of media supply to the system, as only one power connection is needed

- With protector version, the grippers are suitable for clean rooms

Scope of delivery:

- 1x LiFo storage unit

- 1 set of workpiece carrier holders ( = 7 pieces)

- Documentation and user manual

- Control software

To ensure flexibility, workpiece carrier holders are used in the LiFo storage system, which are provided with component-specific workpiece nests. Please note that all parts in contact with the workpiece (for example gripper finger, workpiece carrier attachment) are not included in scope of delivery.

In order to get to know the individual functions of the LiFo storage system, a training session at our Lederhose facility for 1 - 5 persons is included.

We are happy to offer you various additional services for the LiFo storage system (prices on request):

- Constructive design of the gripper finger geometry according to your specifications and/or taking into account other specifications, optionally incl. manufacturing

- Constructive design of the workpiece carrier attachment, optionally incl. manufacturing or 3D printing

- Complete commissioning at mkf incl.:

- Constructive machining, manufacturing and assembly of the workpiece attachments

- Constructive machining, manufacturing and assembly of the gripper fingers

- Creation of the corresponding recipe

- Training at your company

- Commissioning of the LiFo storage at your site and verification of the interface(s)

Your contact persons in the department of sales automation solutions

Lars Palmi

Project Sales Automation Solutions

- phone.: +49 36604 8860

- Mobile: +49 159 04098969

- vertrieb(at)mkf-automation.de

Chris Beierlein

Internal Sales Automation Solutions

- phone.: +49 36604 8860

- vertrieb(at)mkf-automation.de

Piet Hötger

Head of Sales

- phone.: +49 36604 8860

- mobile: +49 172 8571898

- vertrieb(at)mkf-automation.de