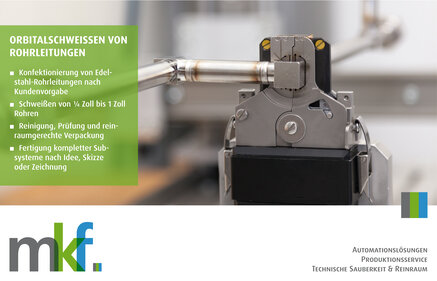

We manufacture individual solutions in the areas of piping (incl. connecting parts) and complete subsystems according to customer specifications using orbital welding processes. The stainless steel piping is tested by us, cleaned in a cleanroom and packaged in a cleanroom.

![[Translate to English:] Orbitalschweißen von Rohrleitungen](/fileadmin/_processed_/b/b/csm_3_2_Orbitalschweissen_unsere_Leistungen_5065c35f89.jpg)

Our services in detail:

- Welding of stainless steel pipes in the range ¼ inch to 1 inch

- Fabrication of complete subsystems according to idea, sketch or drawing

- Helium leak test ISO 10-9 mbar

- Fabrication of stainless steel piping with connecting parts according to your specification

- Clean room compatible cleaning and packaging according to DIN ISO 14644-1

- Process data storage according to your specification

Orbital welding applications:

Orbital welding is a fully mechanical gas-shielded welding process (TIG welding process) in which the arc is mechanically fed 360 degrees around pipes or other round bodies without interruption.

The orbital welding process is preferably used in pipeline construction, especially when sensitive processes require pure media or critical media are used. The consistently high seam quality required for this is achieved under controllable conditions.

Advantages:

- high process reliability

- high repeatability

- high reproduction reliability

- little oxide formation

- highest quality of the weld seam

- lowest contamination of the medium with foreign particles

Further information

Orbital welding of pipelines

- Fabrication of stainless steel piping with connecting parts according to customer specifications.

- Welding is carried out in the range from ¼ inch to 1 inch

- Testing and clean room compatible packaging

- Manufacturing of complete subsystems according to idea, sketch or drawing

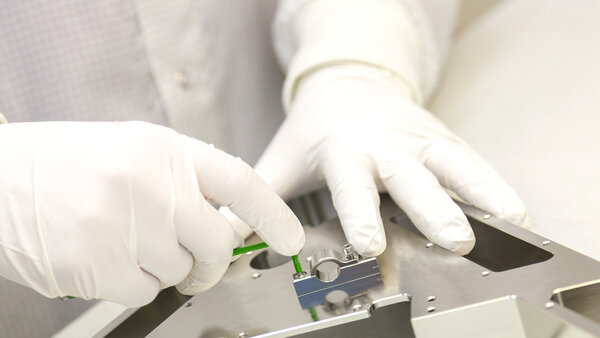

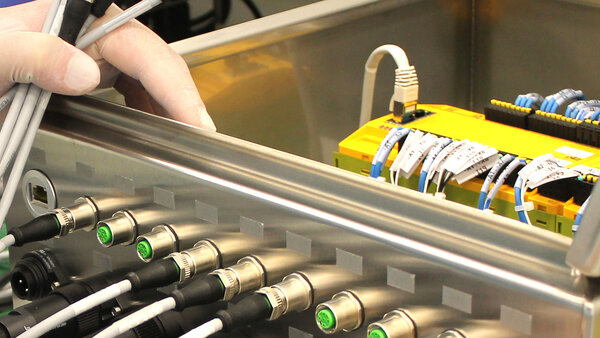

Service portfolio in the cleanroom

- Production of individual parts, components and assemblies under cleanroom conditions

- Cleaning and packaging for cleanroom-compatible production

- Delivery of cleanroom-ready and ready-to-install mechanical, electrical and mechatronic assemblies

- Development of cleanroom workstations and mini-environments

Contact

Michaela Oeser

Technical Sales Production Service

- phone.: 036604 8860

- Fax: 036604 88623

- vertrieb(at)mkf-automation.de

Thomas Bärsch

Technical Sales Production Service

- phone.: 036604 8860

- Fax: 036604 88623

- vertrieb(at)mkf-automation.de

Annegret Weise

Internal Sales Production Service

- phone.: 036604 8860

- Fax: 036604 88623

- vertrieb(at)mkf-automation.de

![[Translate to English:] Orbitalschweißen von Rohrleitungen](/fileadmin/_processed_/4/6/csm_3_2_Header_Orbitalschweissen_aee758f9ba.jpg)