Fully automatic assembly with 19 assembly, testing and processing stations

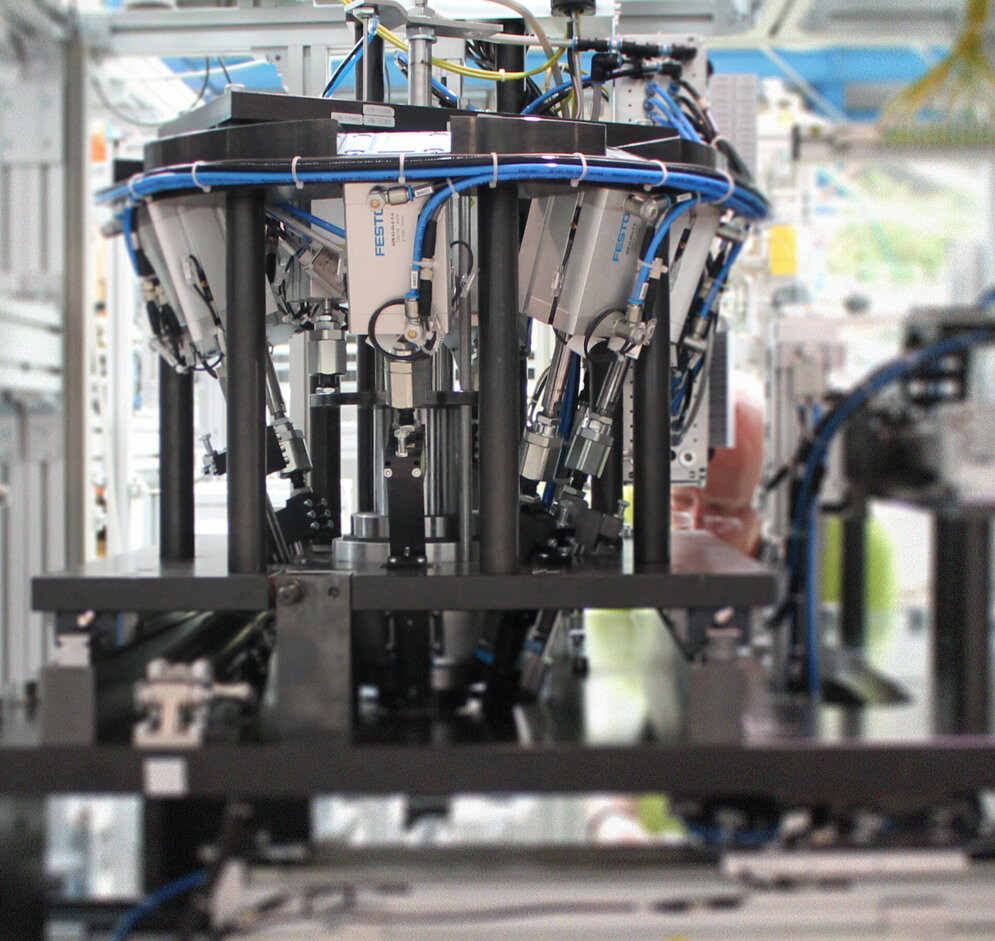

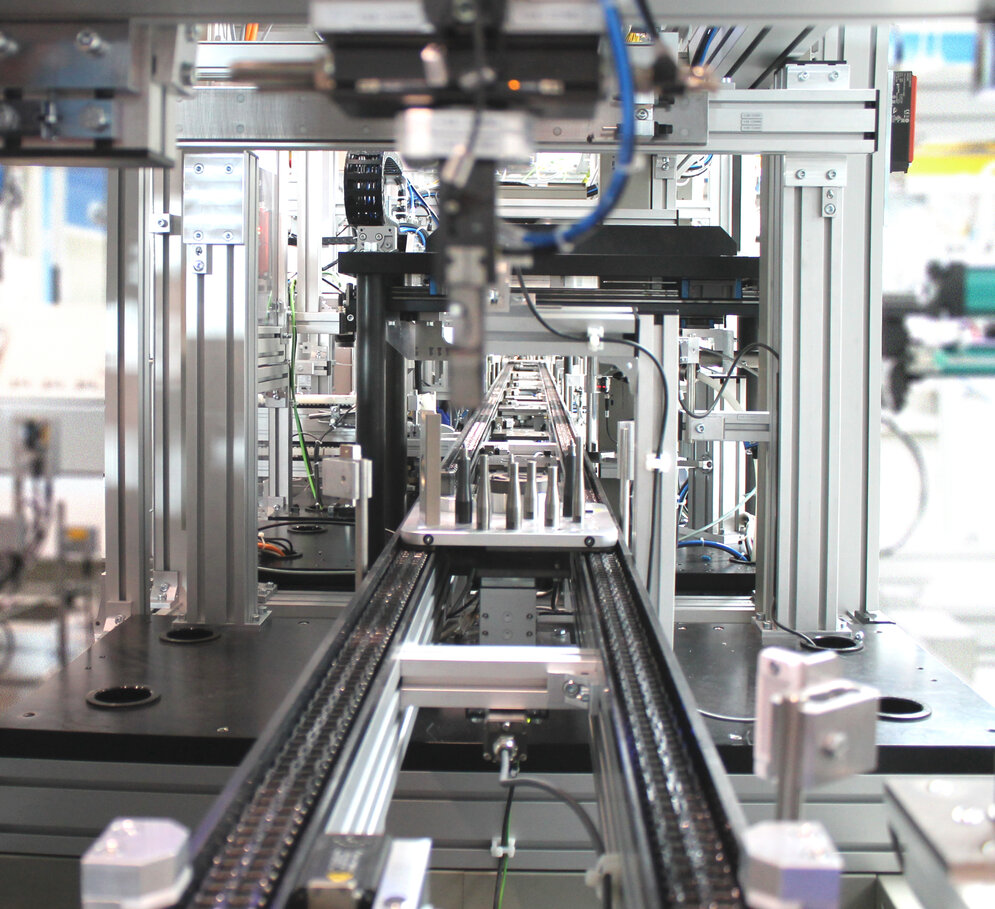

Automatic assembly of the switchover flaps for exhaust gas recirculation is carried out on a modular assembly line at 19 individual stations. The parts to be assembled are transported on workpiece carriers via a circulating transfer system.

At the individual stations, the parts are fed in fully automatically or manually, aligned, checked for completeness, assembled and marked. To compensate for time differences in the individual welding, caulking and assembly steps, the system operates with buffers when feeding the parts and with assembly steps carried out in parallel.

To ensure the high precision of all assembly steps, various test steps (e.g. leak tests, flow tests) and marking processes (e.g. labeling, counter-reading DMC code, needle embossing, labeling of n.o.k. parts) are already integrated into the assembly process.

The 2 welding machines integrated in the plant are protected against unauthorized access by protective fence panels. The doors for maintenance and setup are protected by safety switches and tumbler.

Customer benefit: Modular system concept for efficient assembly of different product variants.

The plant is designed so that different product variants can be assembled. The variant to be assembled can be selected in the plant's program. Additional programs are also available for the assembly of spare parts and rework parts of the changeover flap.

All stations are installed in modules of frames (in defined standard sizes) made of aluminum profile. The advantage of this modular design is that new modules can be efficiently integrated into the system or individual modules can be rebuilt.

All uniform functions in the individual stations, such as stoppers, lifters, sensors, and part queries, are implemented for the most part using standard components, so that fewer different spare parts are required.

learn more:

Reference: Automatic assembly line for switchover flap

- Fully automatic assembly of switchover flaps for exhaust gas recirculation

- the system has 19 assembly, testing and processing stations

- the cycle time is 22 seconds

- The system enables flexible processing of different variants of the switchover flap

Your contact persons in the department of sales automation solutions

Lars Palmi

Project Sales Automation Solutions

- phone.: +49 36604 8860

- Mobile: +49 159 04098969

- vertrieb(at)mkf-automation.de

Chris Beierlein

Internal Sales Automation Solutions

- phone.: +49 36604 8860

- vertrieb(at)mkf-automation.de

Piet Hötger

Head of Sales

- phone.: +49 36604 8860

- mobile: +49 172 8571898

- vertrieb(at)mkf-automation.de