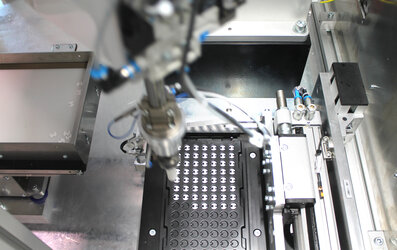

For the production of components for sensors, a semi-automated palletizing of fine ceramic plates is required.

The system is loaded manually with the ceramic parts as loose material and the empty trays. An anyfeeder robot system is then used to separate the ceramic parts from loose material. The position of the individual ceramic parts is identified by means of transmitted light and a camera.

The robot picks up the recognized ceramic plates with a suction pad and places them in the plastic tray provided. When the tray is completely filled, it is changed automatically.

The cycle time is 2.5 seconds. The system can be operated on its own for up to 45 minutes.

Customer benefit: different product variants with different geometries on one plant.

The plant is designed in such a way that different product variants can be palletized. This enables the customer to place different geometries in specific plastic trays with less manpower and higher quality. The operator can choose between 5 different ceramic parts via the article management. The article management can be expanded to include additional parts.

Learn more:

Reference: Palletizing of ceramic parts

- Separation of ceramic parts from loose material

- position detection by means of transmitted light method and camera

- the system allows palletizing of parts with different geometries

Your contact persons in the department of sales automation solutions

Lars Palmi

Project Sales Automation Solutions

- phone.: +49 36604 8860

- Mobile: +49 159 04098969

- vertrieb(at)mkf-automation.de

Chris Beierlein

Internal Sales Automation Solutions

- phone.: +49 36604 8860

- vertrieb(at)mkf-automation.de

Piet Hötger

Head of Sales

- phone.: +49 36604 8860

- mobile: +49 172 8571898

- vertrieb(at)mkf-automation.de