Customer benefit: Precise solutions for many different assembly processes in one plant

The core requirement for the plant concept was error-free handling and precise part delivery into the assembly process as well as the development of an innovative plant concept for the many different assembly and testing steps.

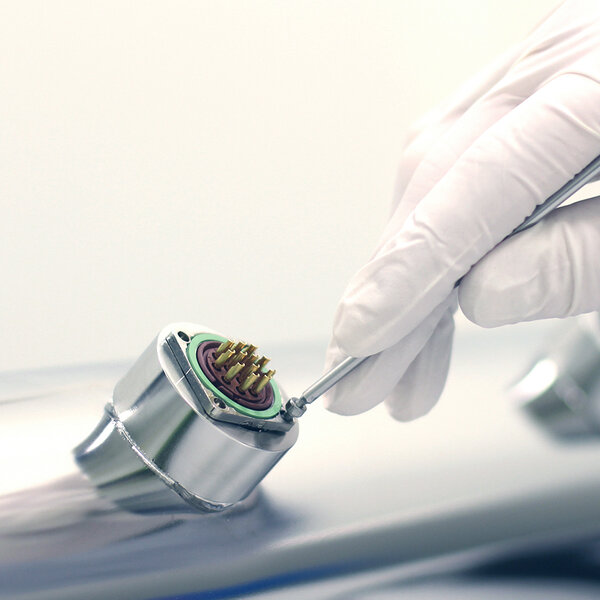

Feeding from bulk material, alignment and assembly of the 18 individual parts takes place in 16 stations. In the process, the individual parts are automatically pressed into place in various stations, welded, screwed and plugged in using a portal-guided welding laser, and the openings are masked with foil to protect them from contamination. Furthermore, the assembled parts can be read out for further processes and are marked for traceability.

The fault-free assembly of the individual parts is ensured several times during the assembly process by means of a leak test. The completely assembled intake manifold module is packed and discharged by a robot.

Step by step to success

- Concept development in consultation with the customer, taking into account the product development still taking place in parallel

- Creation of a functional specification in cooperation with the customer

- Determination of costs, budget and realization time

- Preparation of offer by mkf and order by the customer

- Realization in constant consultation: design meetings, design acceptance, project meetings, status meetings and milestone control as well as preliminary acceptance

- Installation and commissioning of the pre-accepted equipment at the customer's site

- Final acceptance by the customer

- After sales service:

- Extension of the plant:

- additional automatic cells (e.g. robot input and output and automatic hose assembly) to reduce manual processes

- Extensions to produce different variants of the article

- Cycle time reduction to 23 seconds per part through additional modules (e.g. leak testing) and program optimizations

- Conclusion of maintenance and optimization contracts

- Extension of the plant:

Learn more:

Reference: Fully automatic assembly of suction pipe modules

- Fully automatic assembly at 16 machining and assembly stations.

- The individual parts are assembled, tested and labeled

- The cycle time is 23 seconds

Contact

Lars Palmi

Project Sales Automation Solutions

- Phone.: 036604 8860

- Mobile: 0159 04098969

- vertrieb(at)mkf-automation.de

Chris Beierlein

Internal Sales Automation Solutions

- Phone.: 036604 8860

- vertrieb(at)mkf-automation.de