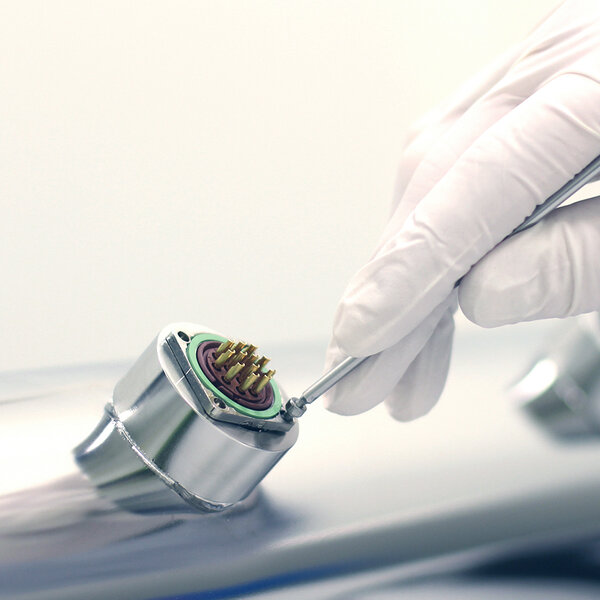

Partially automated mobile assembly workstation

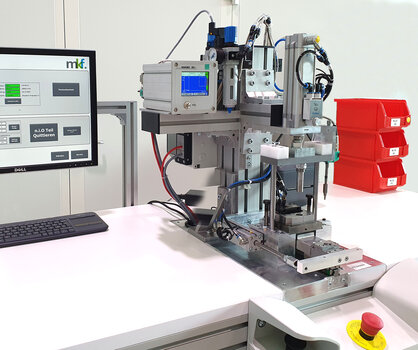

A partially automated assembly workstation was developed for the assembly of filter units for use in medical devices. The assembly workstation enables the filter units and housings to be pressed in consistent quality (fewer n.o.k. parts) and within the specified production time. The workstation is used in the clean room.

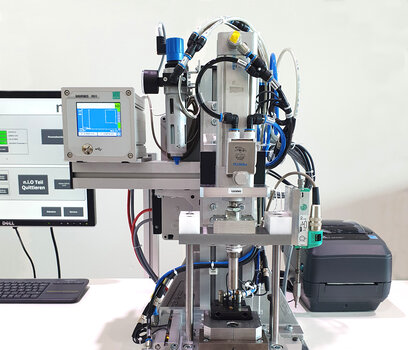

In order to ensure consistently high quality, pressing-in is carried out under monitoring of various parameters. All process data is stored for complete traceability. Furthermore, sequential numbering ensures batch-accurate traceability. The output of the labels can be customized.

Customer benefit: Ensuring consistent quality and batch-accurate tracing of all process parameters

- Consistent quality through monitoring and storage of relevant parameters

- force-displacement measurement during the press-fit process

- individually adaptable user interface

- consecutive numbering

- batch-accurate traceability

- individual label output

- safe operation via 2-hand control

Further Information:

Reference: Partially automated assembly workstation

- Pressing of filter units

- Monitoring and storage of process data

- Batch-accurate traceability

Your contact persons in the department Sales Production Service