Fully automatic assembly of drain fittings

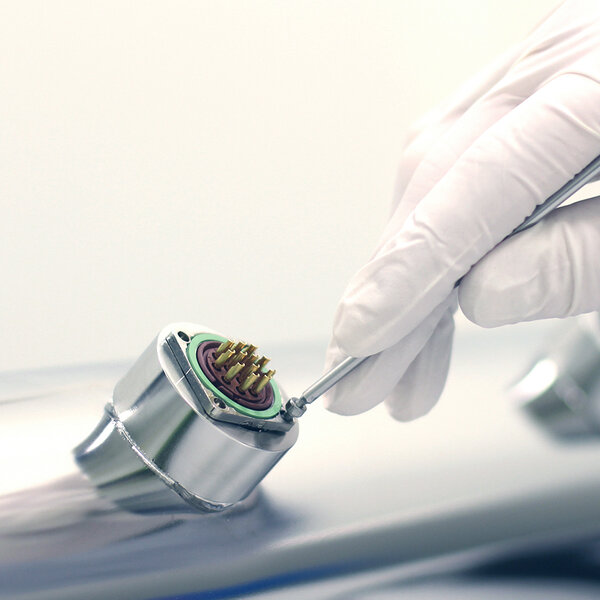

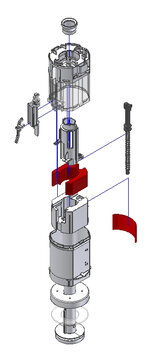

mkf realized the fully automatic assembly of drain fittings for WC cisterns for Sanitärtechnik Eisenberg GmbH (SANIT). The product consists of a total of 14 individual plastic parts. All individual parts are separated from loose material by means of bunker belts, circular conveyors and linear conveyors, aligned and automatically fed to the assembly line. All components are then assembled in a few seconds, inspected, labeled by laser and finally placed in containers in the correct position. The system has a total of 18 assembly and processing stations for this purpose.

Customer benefit: Advanced solutions for flexible performance.

The core requirement for the system concept was the error-free handling of the various plastic parts. These are associated with high tolerances due to their production and shape - unfavorable for the assembly and automation capability of the fittings. For this purpose, mkf developed innovative alignment, centering and positioning units. The assembly process reacts smoothly to the high tolerances of the different plastic parts. In addition, the system and its control system have a modular basic design. This allows SANIT to cost-effectively expansion and retrofitting as well as easy replacement of the modules. The result is a flexible assembly process. The customer-specific changeover to other automation processes is carried out in just a few simple steps.

Project sequence: Step by step to the goal

- Concept development in consultation with the customer, taking into account the parallel product development process

- Active support in product development with regard to automation and assembly capability

- Creation of a specification sheet in cooperation with the customer

- Determination of costs, budget and realization time

- Preparation of offer and order by the customer

- Realization in constant consultation: design meetings, design acceptance, project meetings, status meetings and milestone control, pre-acceptance

- Installation and commissioning of the pre-accepted equipment at the customer's site

- Final acceptance by the customer

- After sales service: Conclusion of maintenance and optimization contracts

learn more:

Reference: Fully automatic assembly of drain fittings

- Fully automatic assembly of drain fittings

- The individual parts are separated from loose material by means of hopper belts, circular conveyors and linear conveyors, aligned and automatically fed to the assembly line

- For this purpose the plant has 18 assembly and processing stations

Contact

Lars Palmi

Project Sales Automation Solutions

- Phone.: 036604 8860

- Mobile: 0159 04098969

- vertrieb(at)mkf-automation.de

Chris Beierlein

Internal Sales Automation Solutions

- Phone.: 036604 8860

- vertrieb(at)mkf-automation.de